|

- Antoine de Saint-Exupery

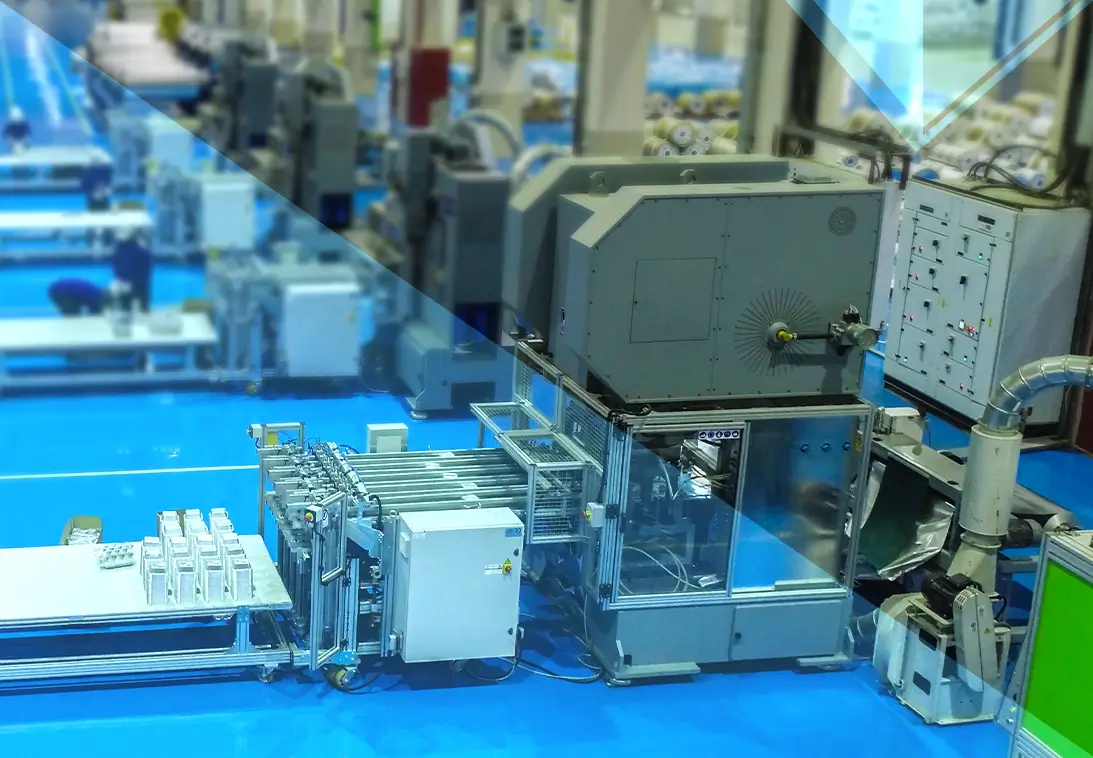

Deployed state-of-the-art equipment and adopted the best in class globally acceptable manufacturing practices.

Technical Parameter for Foil finishing Mill

Make- Achenbach. Germany

Speed- 1200 mpm max.

Strip width- 1250 – 2150 mm

Strip entry Thickness- Max. 0.1mm

Strip exit Thickness- 2x0.006 mm

Coil diameter- Ф Max 1850 mm

Coil weight- Max. 14000 kg(without spool)

Type- 4 hi Non-Reversing foil intermediate mill

Controls- Gauge. shape. & flatness control system

TSP Production Line

Engine Power- Torque motor 55Kw

Stroke Rate- From 1mm to 250 mm

Electronic PLC- Siemens

Vacuum connections- 2

Maximum independent cavities possible- 6

Feeder level adjustment- Electrically

Bed plate dimensions- 1570mm x 800mm

Ram face dimensions- 1100mm x 400mm

Adjustable speed- Min 1 to 120max strokes per minute

Number of solenoid valve connections with adjustable pressure- 18 (3x6 cavities)

Number of fixed connections with adjustable pressure- 12 (2x6 cavities)

Number of Thermo control connections (for paper only)- 6

Foil Feeding- Electronically controlled with brushless motor

Maximum press dimension- 2300mm x 1760mm height 300mm

Feeder level from the bed plate- From 125 to 250mm

Maximum mould height with ram Down adjustment UP- 515mm (with 150mm stroke)

RAM adjustment- 70mm by mechanical adjustment

Maximum mould dimensions- Aluminium 1 mould 1400 x 800mm paper 2 moulds 680 x 800mm

Height from the floor to mould side- 1025 mm

Maximum width of foil passage- 1200mm

T130- Technical Specifications

Press Power(tons)- 130

Engine power(Kw)- 18.5

Stroke rate- Upto 250mm

Vaccum connections- 2

Maximum independent cavities possible- 6

Feeder level adjustment- Electrically

Ram face dimension- 740 mm x 540 mm

Maximum mould dimensions- 1400 x 800

Maximum width of foil passage- 1050 mm

Total Weight- 15.000Kg

Electronic PLC- siemens or Omron or Allen Bradley

Adjustable Speed- Min 40 max 90 strokes per minute

Number of solenoid valve connections with adjustable pressure- 24 (4x 6 cavities)

Number of fixed connections with adjustable pressure- 12 (2 x 6 cavities)

Foil feeding- Electronically co6ntrolled with brushless motor

Feeder level adjustment from the bed plate- From 125 to 275 mm

Bed plate dimensions- 1400 mm x 900 mm

Maximum mould height with ram DOWN adjustment UP- 518 mm (with minimal stroke 150 mm)

ram adjustment- 75 mm (i.e. 518-75=443mm)

Height from the floor to mould side- 1050mm

Maximum press dimension- 2200 mmx 1910 mm height 3550 mm

T63- Technical Specifications

Press Power(tons)- 63

Engine power(Kw)- 7.5

Stroke rate- 200 mm max

Electronic PLC- allen Bradley

Feeder level adjustment- Manual

Bed plate dimensions- 1100 x 800 mm

Ram face dimension- 560 x 560 mm

ram adjustment- 70 mm

Total Weight- 9000Kg

Maximum mould dimensions- 1100 x 800

Number of solenoid valve connections with adjustable pressure- 8 for 16 connections

Number of fixed connections with adjustable pressure- 4

Maximum independent cavities possible- 2

Foil feeding- Electronically controlled with brushless motor

Adjustable Speed- Min 40 max 90 strokes per minute

Height from the floor to mould side- 1050 mm

Maximum press dimension- 2355 mm x 1890 mm height 3300 mm

Maximum width of foil passage- 1050 mm

Feeder level adjustment from the bed plate- from 165 to 270 mm

Maximum mould height with ram DOWN adjustment UP- 460 mm

Rotomac 142.6/470 Technical Specifications

142.6/470 ( 6 spindles)

Outer diameter of mother rolls- 800 mm max

Inner diameter of mother rolls- 150 mm (other diameter on request)

Material width- 280 ÷ 460 mm(120 ÷ 460 mm on request )

Material thickness- 9 ÷ 23 μm

Compressed air- 0.5 - 0.8 Mpa

Overall dimensions L X W X H- 2,800 x 2.500 x 2,000 mm approx

Weight- 2,300 Kg approx

Number of spindles on turret- 6 driven - 6 idle

Mechanical starting device (glueless attachment)- Included

Length of finished rolls- 3-300 m

Outer diameter of finished rolls- 75 mm max

Inner diameter of cores- 25 ÷ 45 mm

Length of cores- 290 ÷ 470 mm( 130 ÷470 mm on request)

Rewinding speed- up to 550 m/min

Number of cycles- up to 40 1/min

Absorbed power- 14.5 kW Max

Electric power supply- 400 V. 50 Hz. 3 ph+O+E (other on request)

Holt melt unit- included

Labelling unit- On request

Cantilevered expansion shaft for cling film- Not available

Perforation unit for plastic film- On request

Curling unit of plastic film- On request

Embossing unit (steel to rubber) for aluminium foil- On request

Micro embossing unit( steel to wool paper) for aluminium foil- Not available

Devices for factory fault diagnostic and remote assistance- Included

Rotomac 145s.6/470G Technical Specifications

145s. 6/470.G (6 spindles)

bsorbed power- 20 kW Max

Compressed air- 0.5 - 0.8 Mpa

Weight- 3500 Kg approx

Holt melt unit- included

Material width- 280÷460 mm

Length of finished rolls- 3 ÷100 m

Inner diameter of cores- 20 ÷ 40 mm

Number of cycles- upto 45 1/min

Labelling unit- On request

Outer diameter of aluminium or paper mother rolls- 1000 mm max

Inner diameter of aluminium or paper mother rolls- 150mm (other diameters on request)

Outer diameter of plastic film mother rolls- 500 mm max

Material thickness- 9 ÷ 23 μm (from 11 μm for micro-embossed foil)

Outer diameter of finished rolls- 60 mm max

Length of cores- 290 ÷ 470 mm

Rewinding speed- upto 800 m/min- upto 350 m/min with micro- embossing unit ON

Inner diameter of plastic film mother rolls- 76.2 mm (other diameter on request)

Electric power supply- 400 V. 50 Hz, 3 ph + 0+ E (other on request)

Overall dimensions L X W X H- 4,000 x 2500 x 2300 mm approx

Mechanical starting device (glueless attachment)- included

Perforation unit for plastic film- On request

Curling unit of plastic film- On request

Embossing unit (steel to rubber) for aluminium foil- On request

Micro embossing unit ( steel to wool paper) for aluminium foil- On request

Devices for factory fault diagnostic and remote assistance- Included

N.1 cantilever expansion shaft for plastic film parent rolls- included

Technical Parameter for Foil Intermediate Mill

Make- Achenbach. Germany

Type- 4 hi Non-Reversing

Speed- 1500 mpm max.

Strip width- 1250 mm - 2150 mm

Strip entry Thickness- Max. 0.35 mm

Strip exit Thickness- Min. 0.011 mm

Coil diameter- Max Ф 1850 mm with spool.

Coil weight- Max 14000 kg (without spool)

Controls- Gauge. shape. & flatness control system